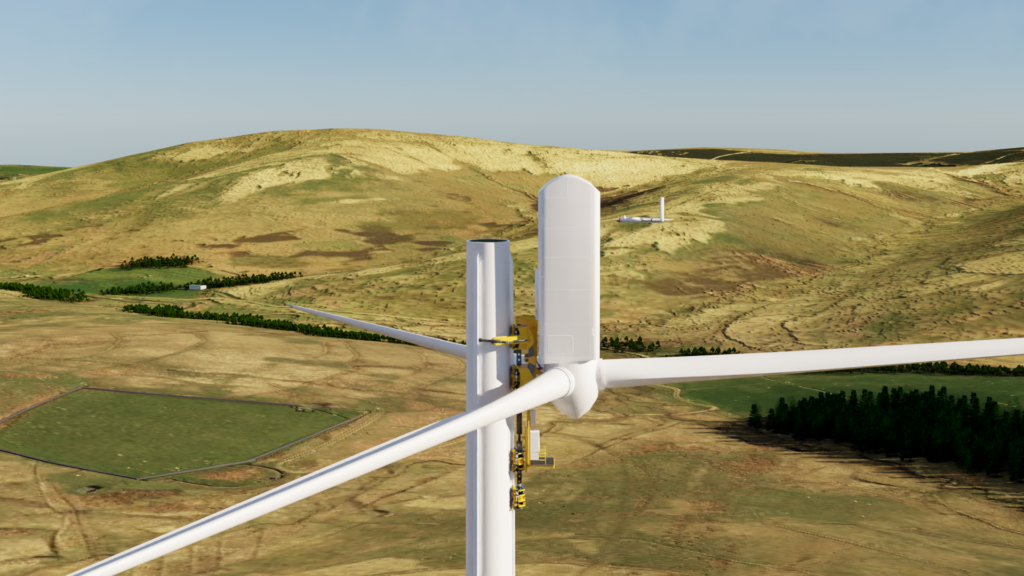

Wind industry innovator SENSEWind has awarded Scotland-based fabricator Forsyths the contract to build the carriage system for its 2 MW onshore demonstration project.

May 15, Glasgow – SENSEWind and Forsyths have agreed to terms on a manufacturing contract to produce an industry-first carriage system in support of the 2 MW demonstration project scheduled for installation in early 2025.

The new partnership, announced today at the All Energy Exhibition and Conference in Glasgow, Scotland, will commence work immediately as plans accelerate toward construction.

The 2 MW demonstrator will feature a Vestas V80 turbine and will be installed at Muirhall Energy’s Tormywheel wind farm and plans to generate power early next year. The project is partially funded by a grant from UK Government’s DESNZ, recognising the important technological step towards scaled-up versions being used for 6MW onshore tall towers and 15MW+ versions in floating offshore wind projects.

The technology is a game-changing solution that looks to solve a host of problems surrounding installation, maintenance, and logistics currently faced by floating wind projects, including those in ScotWind. It will deliver up to 12% reduction in LCoE largely through reducing reliance on quayside ring cranes and offshore floating cranes for installation and major component swap out.

SENSEWind Chair Julian Brown welcomed the news: “We are delighted to be working with the team at Forsyths. Their impressive capability and quick grasp of the manufacturing challenge for the SENSEWind carriage, along with their commitment to the transition to renewables makes them an obvious partner. We look forward to that defining moment next year when the carriage, made by Forsyths, will install the 2MW turbine at the Tormywheel site.”

Forsyths Managing Director Richard E. Forsyth, said, “Forsyths has been offered and accepted this opportunity to collaborate with SENSEWind, solidifying their position as fabrication innovation leaders in the renewables ecosystem. The partnership is a natural outcome of Forsyths’ groundbreaking efforts in fostering collaborative innovation within the dynamic renewables environment. This award is a reflection of our dedication to pioneering a platform where effective collaboration between businesses and innovators becomes the norm. We aim to continue transforming the innovation landscape, making it more accessible and fruitful for businesses worldwide.”

With the Forsyths deal now in place, SENSEWind continues to field conversations with leading wind turbine OEMs and floating wind developers, all keen to see the technology brought to market.

-end

Press Contact:

Julian Brown, SENSEWind

jbrown@sensewind.com

+44 7710 887949

About SENSEWind

SENSEWind Limited (SWL) is a tech innovation company developing solutions for the wind industry to enable rapid turbine installation, major maintenance of large wind turbines, and cost-effective re-powering. With the development of the SENSE concept (Self Erecting Nacelle & Service System), SENSEWind aims to drive down costs and increase the commercial viability of more wind projects across the globe, both onshore and offshore. By design, the concept reduces project risk and scales at the speed of turbine innovation – the larger and more remote wind turbines become, the more value the SENSE concept provides. Modelling forecasts show levelised cost of energy (LCoE) reduction of up to 12% depending on location. The SENSE concept has been successfully demonstrated with an onshore turbine in Ireland and is readying for larger onshore demonstration projects in the UK in 2025. For more information visit www.sensewind.com.

About the SENSE System

The SENSE (Self-Erecting Nacelle & Service) System installs, services, and decommissions large wind turbines without extra-large special cranes or crane vessels. The technology is aimed at the sector’s otherwise inaccessible sites – onshore tall towers and deep waters offshore.

The SENSE System simplifies operations and reduces costs during development, construction, and operations, and increases revenue through higher availability. The value delivered to a project comes in many forms:

- Use standard construction vessel for RNA transport and transfer to tower

- Undertake inspections and maintenance without tall cranes

- No large expensive cranes or crane vessels for RNA installation

- Reduces number of lifting operations during installation

- Eliminates the need for handling systems within the turbine to repair/replace major components

About Forsyths

Forsyths Ltd is the fabrication arm of the Forsyth Group based in the North East of Scotland, covering several industrial sectors including oil & gas and renewables. In the oil and gas sector, Forsyths designs and manufactures a wide range of equipment in numerous grades of material. Typical fabrications include structural steel work, piping, pressure vessels, umbilical/pipe reels and tanks. Within renewables and low carbon hydrogen, the company is a key resource to Scotland’s energy security, focusing on fabrication engineered with a lifetime of skills, and holds expertise in areas such as innovation design, platforms and handrails, and bespoke fabrication design.