With apologies to Bob Dylan!

Wind turbine tower design and manufacturing is one of the lesser-known success stories of the global wind industry.

What looks like a simple tube is in fact a complex structure fabricated from steel plates of varying thickness, rolled into cans which in turn are welded together. The manufacturing process is highly optimised and competitive. Even though individual wind farms often have bespoke designs, towers are treated as a commodity item.

Current tower designs are highly tuned to match requirements in stiffness, vibration, fatigue life, extreme load and cost. Behind the scenes in every WTG OEM is a team of tower design specialists keeping up with each project.

The challenge is that next generation wind farms will require an entirely different solution.

Onshore wind is evolving to taller towers to benefit from wind shear (there’s more wind the higher you go) and onshore installations are already constrained in height and turbine size by tower logistics to site due to tower diameter. Tubular ‘stacked can’ based towers have to grow in diameter and wall thickness to be viable. Above around 160m hub height hybrid steel/concrete towers are preferred but if you go any higher, another solution is needed – a solution which can be delivered to site and doesn’t require a monster crane.

Floating offshore wind has a different challenge – in addition to matching larger turbine size, the tower stiffness must also match the specific requirements of the floating foundation on which it is mounted. Staying with conventional tubular steel towers puts further pressure on diameter and wall thickness.

Floating project developers are still seeking the magic sweet spot of the best combination of floating foundation and WTG tower design. Tower wall thickness is approaching 100mm at which point it almost becomes un-manufacturable. That’s if you can even source the steel!

With the challenge widely recognised, hybrid towers have been around in some markets for a while and can certainly go higher, but they don’t solve the installation challenge.

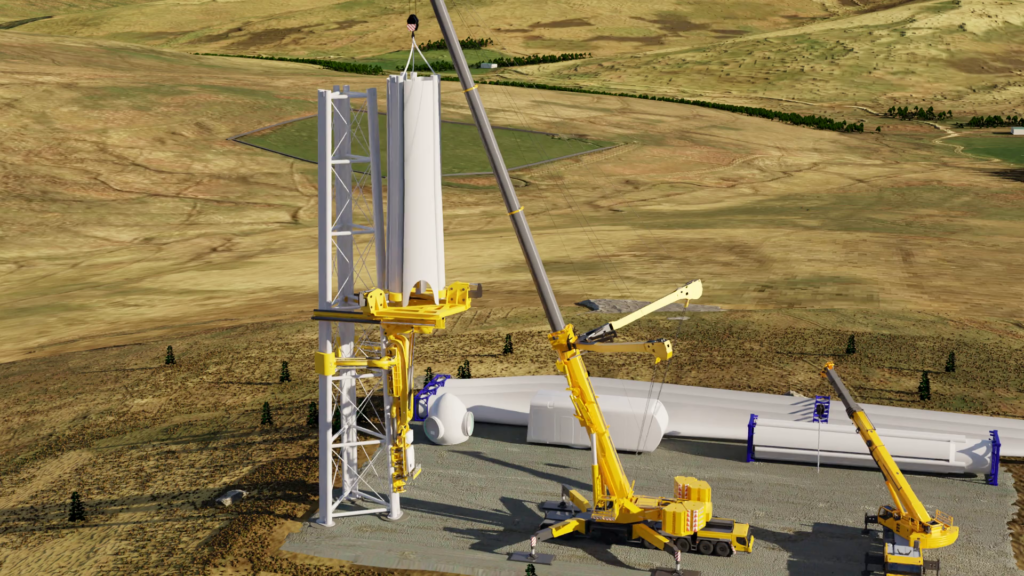

SENSEWind has just launched the solution: an innovative tower concept to build taller towers onshore and stiffer towers on floating projects offshore – all incorporating rails to enable self-installation of both tower sections and rotor nacelle.

The core technology is a tripod concept utilising pairs of ‘riser tube’, extensively used in the oil and gas industry. The lattice structure can be left open or fully enclosed as required at different heights. The magic of this solution is that the legs become the ‘rails’ for the SENSEWind self-installation carriage to climb for both tower section and rotor nacelle assembly.

If the feedback from industry on the concept last week in Manchester is any indication, this technology is not only promising, but truly game changing.