SENSEWind set to build 6 MW turbine in Scotland using innovative installation system

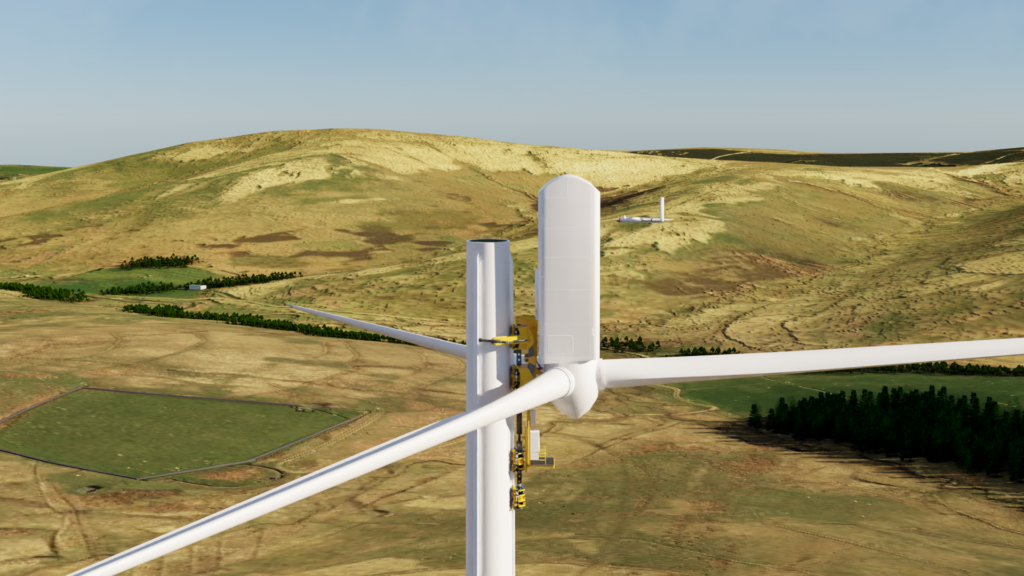

Adding to its pipeline of demonstration projects, UK-based SENSEWind plans to construct a 6 MW wind turbine in Scotland using its innovative SENSE installation system.

SENSEWind signs manufacturing contract with Forsyths to build carriage system

SENSEWind and Forsyths have agreed to terms on a manufacturing contract to produce an industry-first carriage system in support of the 2 MW demonstration project scheduled for installation in early 2025.

Video: ‘Self-installing’ wind turbine solution set for UK test

A wind installation company that employs robotics to “self-install” turbines plans to demonstrate its concept with a 2MW onshore machine and eventually use its technology for floating projects.

SENSEWind awards industry-first triple rail tower contract to SM Industries for 2 MW BEIS demonstration project

SENSEWind has selected SM Industries (formerly Valmont) to produce a first-of-its-kind, triple rail wind turbine tower for its flagship 2 MW onshore demonstration project – a single turbine plan partially funded by UK Government (BEIS) FOW grant scheme.

Opinion: Solving the Tow-Back Challenge in Floating Wind

On the O&M side of things, based on evidence generated from a series of industry engagements, BVG Associates estimate* that a future 1 GW floating wind farm of 70 turbines would plan for at least seven major component exchanges per annum in early post-warranty years.

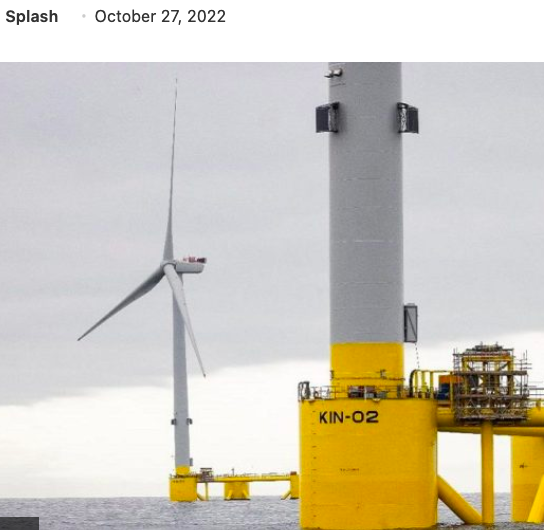

DNV predicts that floating wind will generate 264 GW, or 15% of all offshore wind energy, by 2050.

The offshore wind industry would be well served to sharpen its focus toward installation and O&M technology advances designed with floating wind in mind. Now is the time to put promising on-site solutions, like SENSE technology, through their paces – before the jump to industrial scale.

Are self-installing wind turbine technologies the answer to avoiding tow-to-shore?

Great article by Heidi Vella in reNEWS – Renewable Energy News this week looking at a number of the technologies (including SENSEWind) being developed to address the challenge of self installing wind turbines for #floatingoffshorewind. It’s clear that ‘tow back’ is not a viable option for O&M.

Floating offshore wind challenged by supply chain conundrum

Excellent read here from Mark Goalen in Splash247 – operational factors will have a massive impact through the floating wind lifecycle. On-site solutions will be a necessity.

Floating Offshore Wind 2022

SENSEWind is attending Floating Offshore Wind 2022. Contact Patrick Geraets or Sandra Eager to hear about our solution for rapid installation and servicing of large wind turbines without the need for expensive cranes or crane vessels!

Julian Brown, wind industry veteran professional and non-Executive Director, assumes Chair role at SENSEWind

Christopher Nash, a co-founder who has guided SENSEWind as Board Chair through the pre-commercial phase, remains on the Board as a non-Executive Director.